Following our initial work in Bridgeland in Cypress, Texas, our team was excited to continue the vision alongside Project Luong, DL Meacham, Bridgeland, and Landology. In 2022, we fabricated several pavilions for the renowned community, each with its own unique personality. This next project centered on fabricating four identical, intricate butterfly structures, a project that blended technology and craftsmanship.

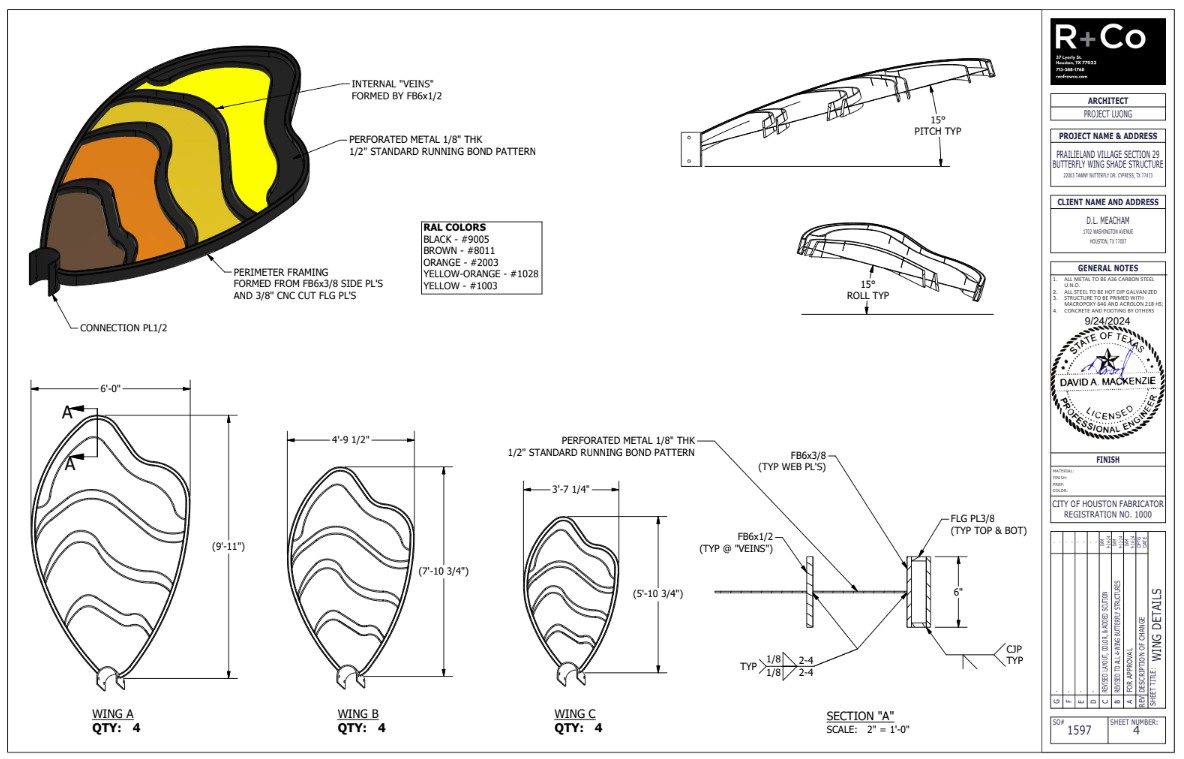

Our first task was to translate the architectural plans through deep structural analysis and engineering. This process was hands-on and collaborative, and with the architects present and supportive, we were able to turn their vision into structurally sound designs.

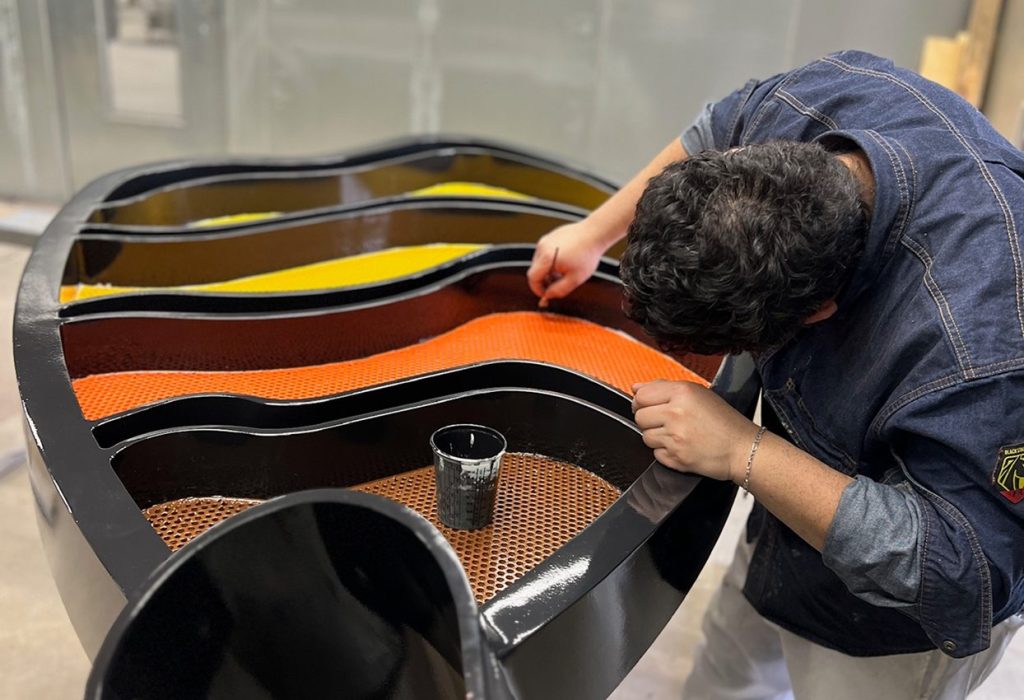

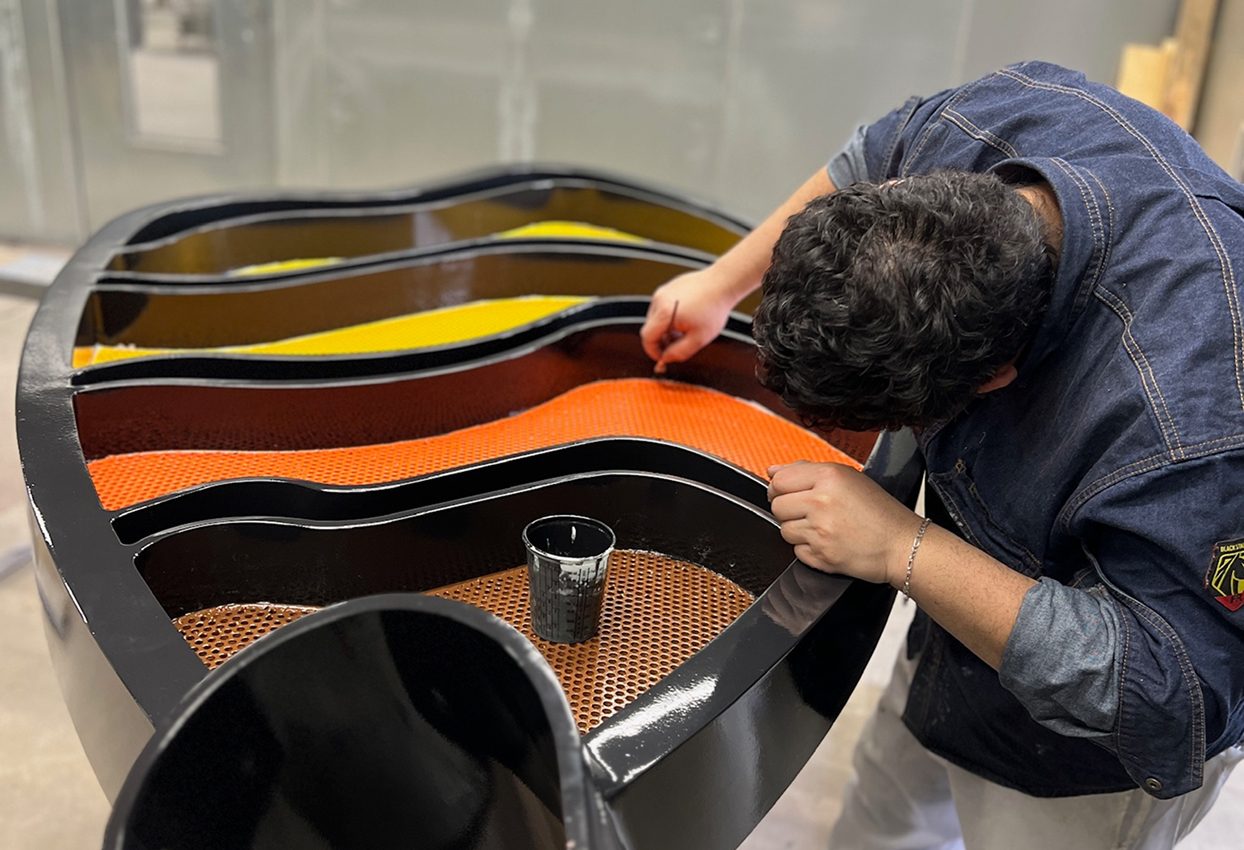

Even with advanced technology, the skills needed for this project were rooted in traditional metalsmithing. Our fabricators hand-formed massive 1/2″ x 6″ metal bars, showcasing the true workmanship at the center of the project. Working at a breakneck pace, we guided communication between all parties to ensure we delivered on time. This dedication continued through to the finishing process, where each piece was hand-taped and masked with extreme care to achieve the clean lines of the Tnemec multicolored finish.

After that, each butterfly structure was fully assembled and test-fit in our shop. This step allowed us to check for stability and make final quality checks that aren’t possible in the field. We also fabricated large, custom escutcheon plates to hide the anchors holding the structures. In the end, the true stars of this job were our fabricators and finishers – their skill and dedication brought these complex butterfly structures to life.

Who: Project Luong, DL Meacham, Bridgeland, Landology

What: Pavilions and Structures

Where: Bridgeland, Cypress, TX

How: Design Build, Engineering, Fabrication, Installation

Renfrow+Co